High precision syringe barrels labelling – Intrex project for Radiometer

Radiometer turned to us because they needed a machine that would be able to apply

Our specialist will be happy to answer your questions about this category of equipment.

Our specialist will be happy to answer your questions about this category of equipment.

Our specialist will be happy to answer your questions about this category of equipment.

Our specialist will be happy to answer your questions about this category of equipment.

Our specialist will be happy to answer your questions about this category of equipment.

Homepage » Products » Pharma industry » Intrex blister labelling system – LSC- 100

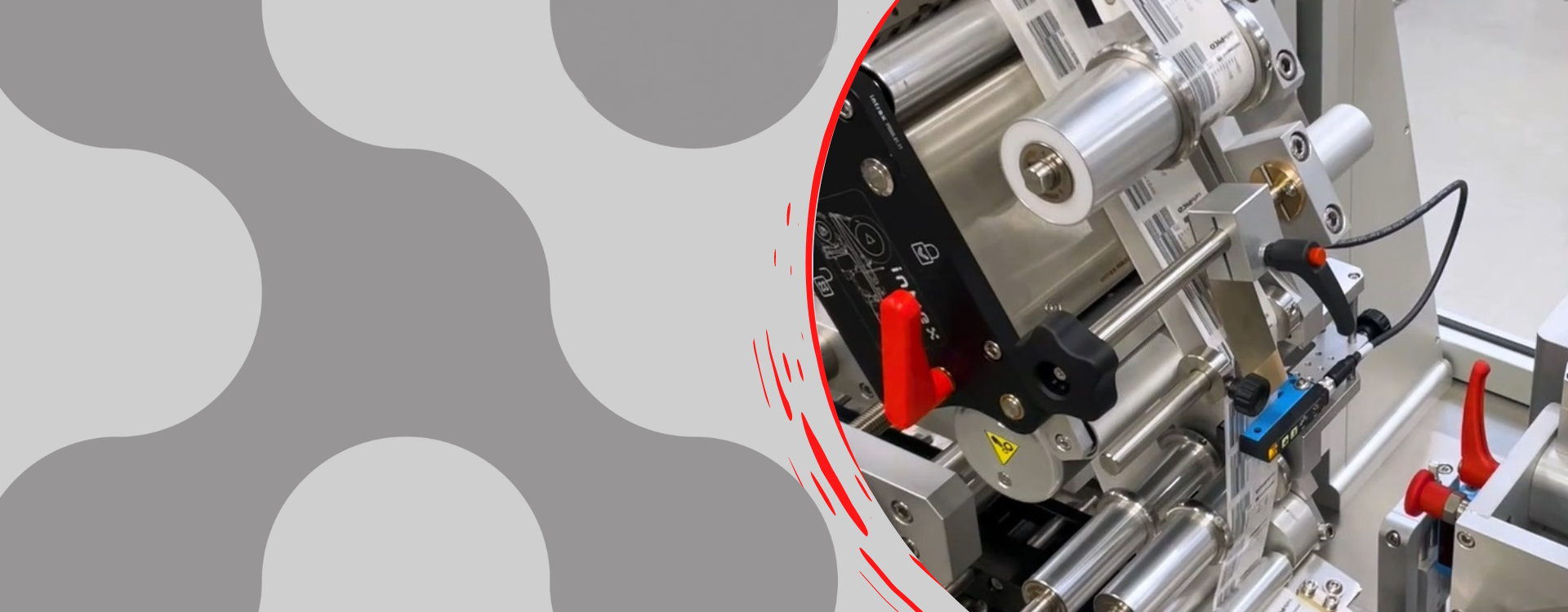

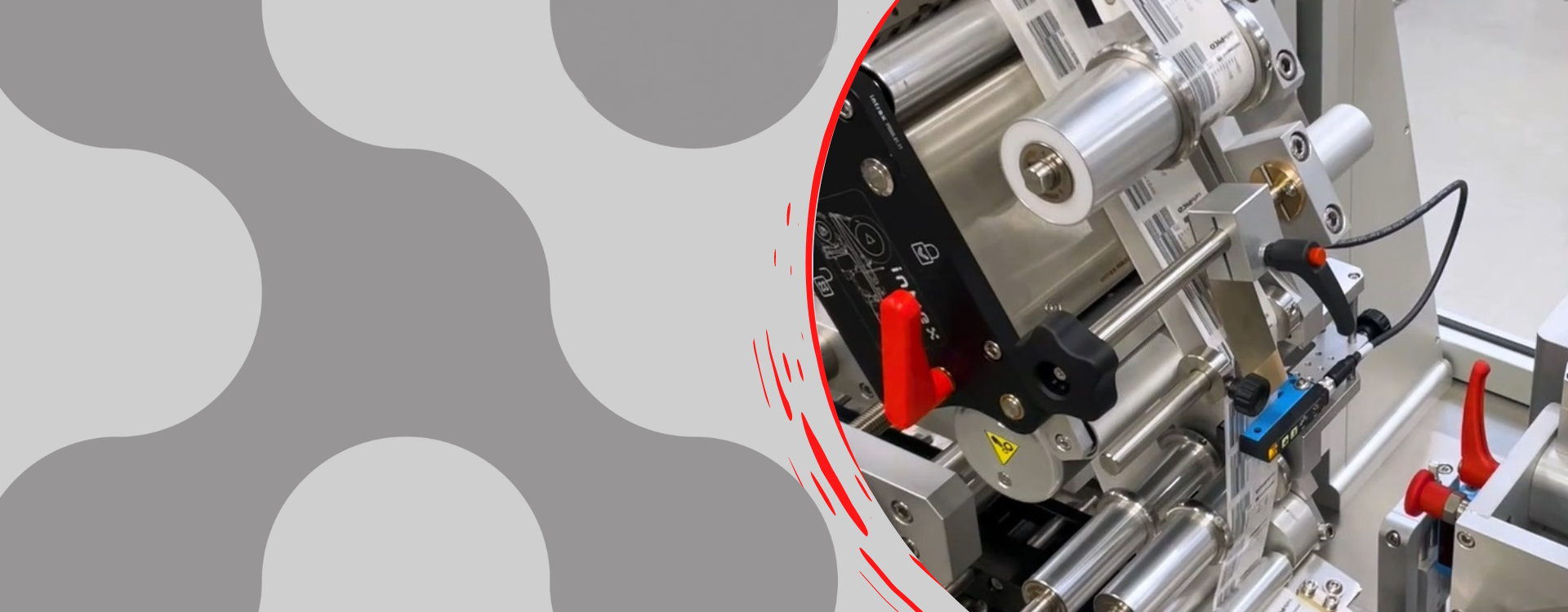

Intrex has designed LSC-100 Labelling system to handle various blister sizes in terms of marking and personalizing according to current needs. Additionally modular device construction allows to expand capabilities and cover different formats and products. User friendly software KUP Vision manage the entire unit. It is also equipped with communication ports to integrate with existing ERP systems.

Short start-up time . Quick setup of the storage magazines, the printer and inspection unit.

Fully automatic changeovers and production . Printer, vision system, product magazines setup change automatically.

Intrex 200 + labelling head integrated with Domino thermal-transfer overprinter ensures application of pre-printed labells with the highest precision and accuracy.

Automatic camera control accompanies every work step - Cognex. During feeding as well as during printing and labelling, the products are checked with high-performance cameras and checked for confirmity with the order data.

Machine meets all safety and pharmaceutical standards. The design of the LSC-100 complies with the EC Machinery Directive 2006/42/EC, EU-GMP, GAMP 5 and also meets FDA (np. 21 CFR Part 11) requirements.

| Maximum label width | 160 mm |

| Max. diameter label roll | 400 mm |

| Vision system | Cognex |

| Capacity | Up to 140 products per minute |

| Blister formats | Form: 61 x 75 x 4,75 mm ; to 65 x120 x4 mm |

| Number of product slots | 10 |

*The technical parameters given on the website apply to specific conditions.

We are a company that responds comprehensively to your needs.

We have already sold thousands of products. We offer individual solutions.

Pharma industry

Pharma industry

Radiometer turned to us because they needed a machine that would be able to apply

The collaboration with Domino and K&P has resulted in a system that combines high throughput

Discover 5 reasons why replacing traditional methods of marking bulk packaging with the modern piezoelectric

You can resign at any time

Selected file:

brak