High precision syringe barrels labelling – Intrex project for Radiometer

Radiometer turned to us because they needed a machine that would be able to apply

Our specialist will be happy to answer your questions about this category of equipment.

Our specialist will be happy to answer your questions about this category of equipment.

Our specialist will be happy to answer your questions about this category of equipment.

Our specialist will be happy to answer your questions about this category of equipment.

Our specialist will be happy to answer your questions about this category of equipment.

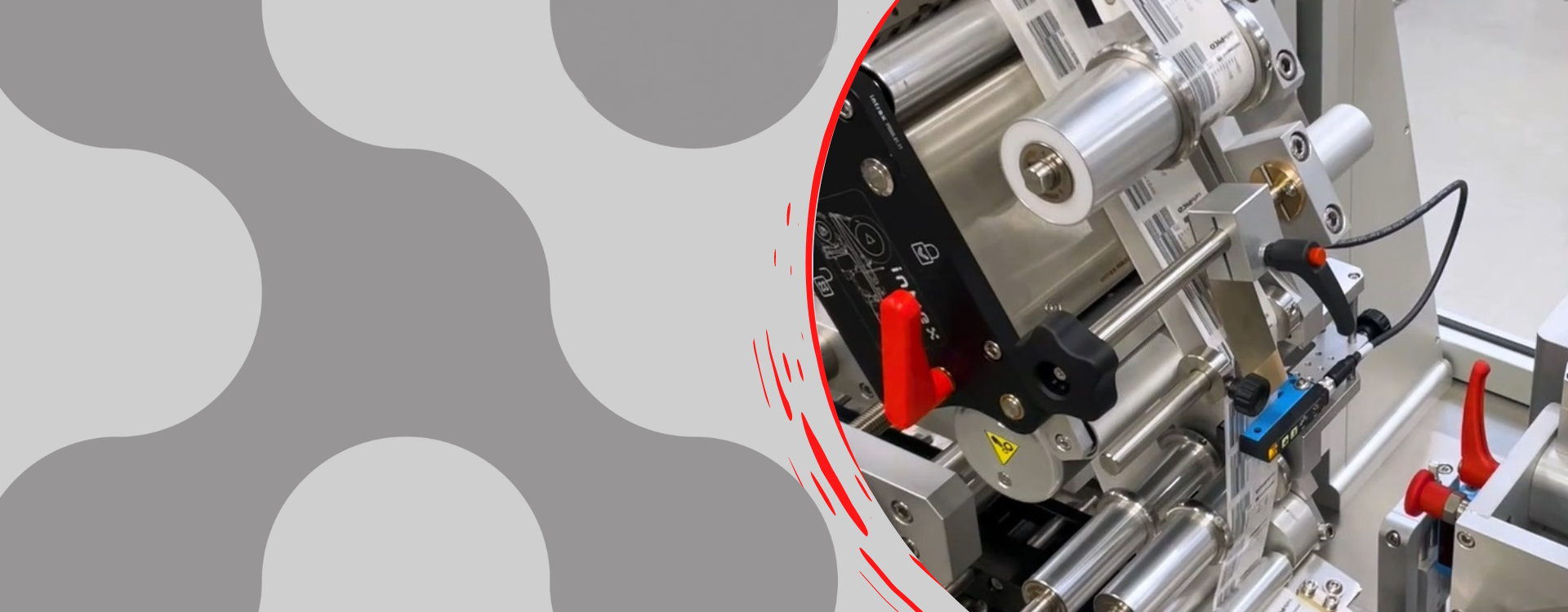

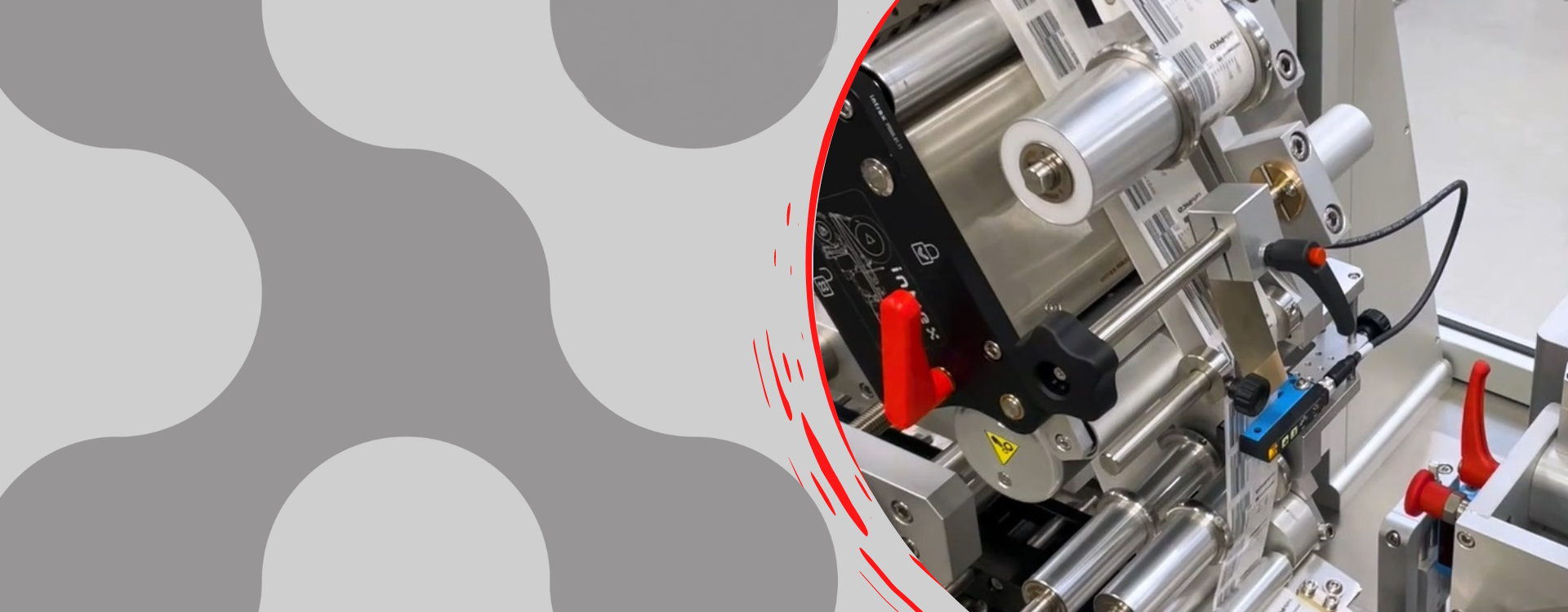

Well proven design of our Intrex 100+ series labelling head provides a versatile and convenient solution for low and medium capacity production lines. Designed to make everyday use as simple and quick as possible, at the same time minimising maintenance and operation cost.

Compact design

Quick label replacement thanks to rollers numbering

Detachable control panel can be installed in a convenient area

Good value for money

| Max label web width | 90 mm, 160 mm |

| Max label roll diameter | 300 mm / 500 mm (external unwinder) |

| Label sensor | Optical, ultrasonic (option) |

| Label feed speed | Up to 27 m/min |

| Label feeding precision | +/- 0,8 mm |

| Memory | 16 programs |

*The technical parameters given on the website apply to specific conditions.

We are a company that responds comprehensively to your needs.

We have already sold thousands of products. We offer individual solutions.

Labelling heads, Labelling

Labelling heads, Labelling

Radiometer turned to us because they needed a machine that would be able to apply

The collaboration with Domino and K&P has resulted in a system that combines high throughput

Discover 5 reasons why replacing traditional methods of marking bulk packaging with the modern piezoelectric

You can resign at any time

Selected file:

brak