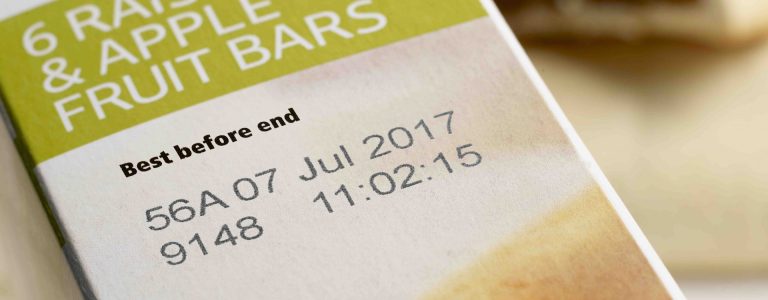

INTREX SET 2704 plus non-stop – automatic labelling system for European manufacturer of chocolate bars

Another project for European leader of the confectionery market. This time the company needs to

Our specialist will be happy to answer your questions about this category of equipment.

Our specialist will be happy to answer your questions about this category of equipment.

Our specialist will be happy to answer your questions about this category of equipment.

Our specialist will be happy to answer your questions about this category of equipment.

Our specialist will be happy to answer your questions about this category of equipment.

The main feature of this machine are two conveying belts separated by a small gap between them that enables labelling from the bottom. It is designed especially for low height and flat products such as trays, blisters and the like.

Simple and versatile solution for flat products labelled from the bottom

Versatility and easy changeovers

Simple and compact design requires less space

| Max label liner width | 90 mm or160 mm |

| Max label roll diameter | 300 mm (option 350) |

| Label sensor | Optical, ultrasonic (option) |

| Labelling speed | up to 100 pcs/min |

| Possible product diameter | 30-200 mm |

| Conveyor length | 2000 mm |

*The technical parameters given on the website apply to specific conditions.

We are a company that responds comprehensively to your needs.

We have already sold thousands of products. We offer individual solutions.

Top and bottom labelling, Labelling

Top and bottom labelling, Labelling

Another project for European leader of the confectionery market. This time the company needs to

Intrex facing opportunity of making a project involving automatic labelling of chocolate bars for one

Hygiene and disinfectant. One of the leaders of the hygiene market entrusted Intrex with a

You can resign at any time

Selected file:

brak