INTREX labelling systems for sanitiser products manufacturers and co-packers

Main features and advantages Machines ready to apply labels on cylindrical and flat products –

Our specialist will be happy to answer your questions about this category of equipment.

Our specialist will be happy to answer your questions about this category of equipment.

Our specialist will be happy to answer your questions about this category of equipment.

Our specialist will be happy to answer your questions about this category of equipment.

Our specialist will be happy to answer your questions about this category of equipment.

Intended to label bottles flattened on both sides. Main control unit made of legible touch panel to support both labelling heads and lines, providing one-stop intuitive access to the most important device settings.

Ease of refitting

Product centering station

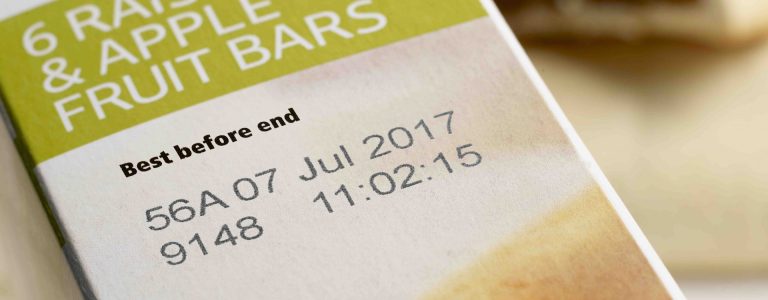

Availability to add thermotransfer printer for barcodes and other alfanumeric figures

Intuitive 5' high quality touchpanel

| Max label liner width | 90, 160 or 220 mm |

| Max label roll diameter | 300 mm (optional 350) |

| Label sensor | Optical, ultrasonic (optional) |

| Labelling speed | up to 250 pcs/ min |

| Possible product diameter | 30-100 mm |

| Conveyor length | 2500 mm |

*The technical parameters given on the website apply to specific conditions.

We are a company that responds comprehensively to your needs.

We have already sold thousands of products. We offer individual solutions.

Side labelling, Labelling

Side labelling, Labelling

Main features and advantages Machines ready to apply labels on cylindrical and flat products –

Another project for European leader of the confectionery market. This time the company needs to

Intrex facing opportunity of making a project involving automatic labelling of chocolate bars for one

You can resign at any time

Selected file:

brak