Spis treści

ukryj

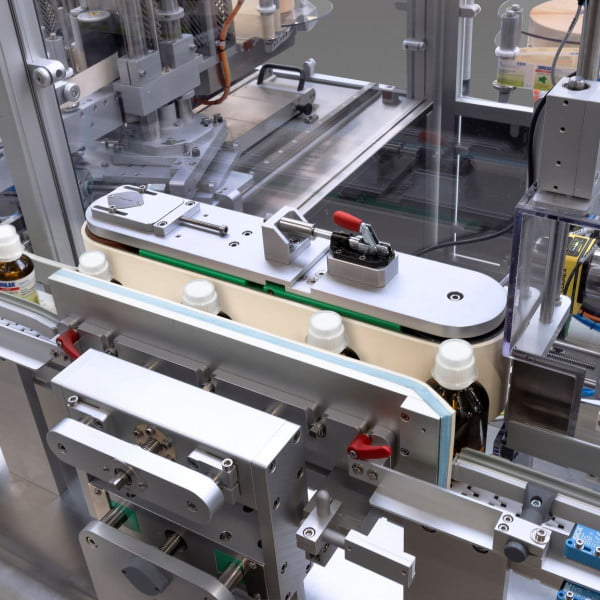

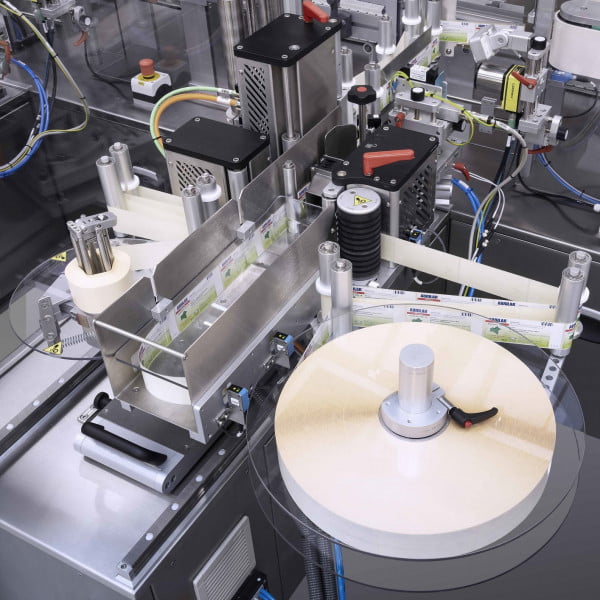

Together with our partners from Intrex Deutschland and K+P we created tailor made labelling line for our customer in Germany. This wrap around unit is crucial for customer production flow and this is main reason for implementation of Non-Stop labelling module. This allows customer to run line without stops for label change-over or printer consumable refill.

Another important feature was implemented by our partners. KuP Vision software allows to control all modules of machine including printer and camera from one panel.

Main features and advantages

- Capacity up to 220 products per minute

- Non-Stop work mode – 2 labelling modules

- Integration with Domino TIJ printer

- Cognex Camera verification of overprint and labelling quality

- Easy access to applicators in service position

- Dedicated KuP Vision software – all modules integrated and controlled from main Beckhoff panel

Technical data

Max label web width ➡ up to 90 mm

Product width ➡ up to 80 mm

Verification ➡ Cognex – over print and label position

Software ➡ Pharma standard compliance (KuP Vision software)

Product separation ➡ Active side belts (infeed)

The technical parameters given on the website apply to specific conditions.

- “Challenges like this, makes our work even more interesting. Customer requirements were clear from day one. Line must be able to work in non-stop mode. Each part of the machine was carefully designed not only to be reliable, precise and work with high capacity but also with great focus to make daily work of operators as easy as possible, and access to critical consumables or wear and tear parts as easy as it can be”

- Krzysztof Spychała Export Development Manager