Intrex labelling system for high-speed bottling lines - Case Study in Sulewski Brewery

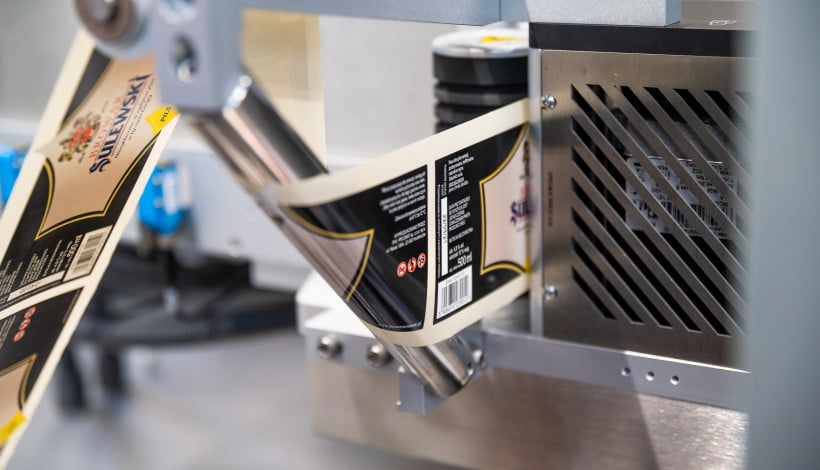

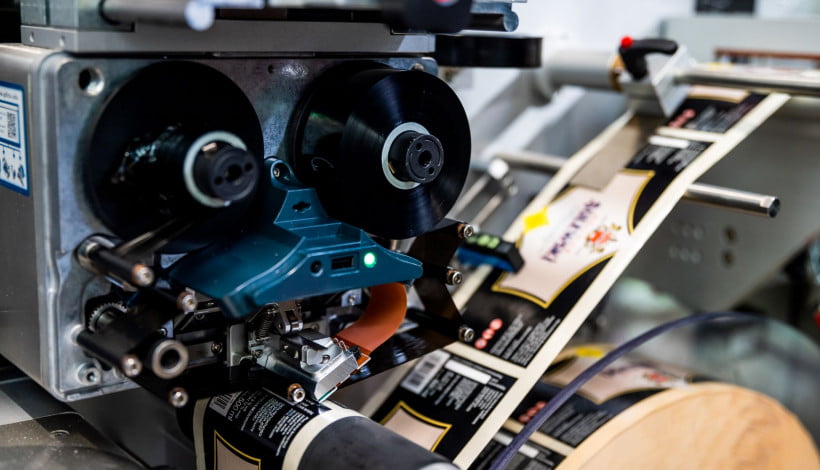

For our client, a brewery, we have designed a solution for wrap-around labelling glass bottles with thermal transfer overprinting.

Browar Sulewski – beer created with passion

Browar Sulewski was founded in 2010, in the old military casino building. Starting from a small family brewery with a restaurant and pub, 6 types of beer are produced today. One of the owners – Mr Tomasz Sulewski drew his knowledge of brewing beer in Bavaria itself, where he trained among the world’s best brewers.

Bigger Brewery, new production line

Passion combined with commitment made the Sulewski family to build a second, larger brewery with a new production line.

Currently, several types of beer are brewed, each with a different label that with an expiry date printed on it. Craft beer is not only a unique taste, but also a carefully selected and aesthetically applied label:

- „The first thing the customers sees looking at the product is the label. Providning all necessary information it the explains what the product is and helps establish brand recognition.”

- Tomasz Sulewski, CO - OWNER

Quality and flexibility in the selection of solutions

We have designed and implemented a system precisely tailored to the needs of the new production line. The Intrex SET 2091 PLUS labelling system is a device based on a rotary star module, labeling with a capacity of up to 6,000 products per hour, while maintaining stability and repeatability of the application. The Domino V120i thermal transfer overprinter, despite its small dimensions, enables the content of labels to be completed with variable data, such as: production date and batch number.

Main features and advantages

- High capacity – up to 100 products/minute

- Rotary transport module ensuring stability and repeatability

- Intrex SMART Panel – intuitive control panel. It allows you to operate all machine functions and the entire labeling process in one place

- Legible and durable print on the label